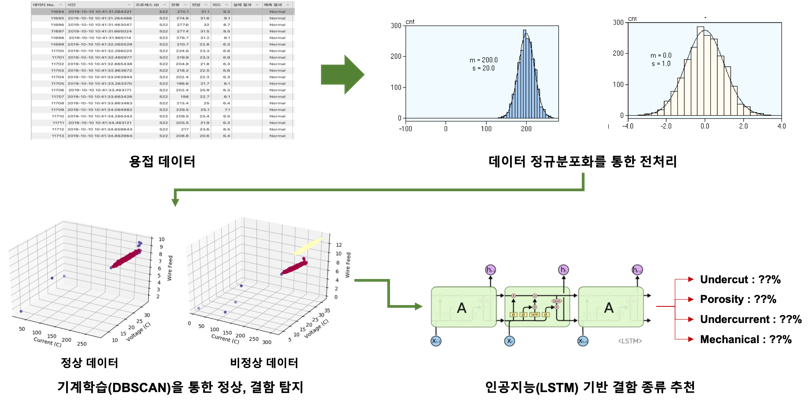

Big Data Based Defect Detection and Prediction

To detect the defect occurred during arc welding process, various techniques are developed such as x-ray, sonic detection and etc. However, since these conventional defect detection techniques are rely on human judgment or heuristics, the defect detection process requires many resources such as time, equipment. To handle these problems, we developed A system which predict the welding defect using current, voltage and wire feed values. The system collects current, voltage and wire feed values from welding machines and determine the start and end time of welding process. Then, the system determines the defect is occurred or not during welding process using clustering based machine learning technique. After defected is predicted the system, also, calculates the probability of defect type using recurrent neural network. We expect the system can reduce resources which is required to detect welding defect by removing the requirement of human judgment.

International

[Conf]Timely Login Status Coantrol Using Mobile App

SeokHwan Choi, Da-Hyeon Kim, Yoon-Ho Choi

IEEE Conference on Communications and Network Security (CNS) 2015

[SCIE]Software-Defined Network-Based Vehicular Networks: A Position Paper on Their Modeling and Implementation

Lionel Nkenyereye, S. M. Riazul Islam, Yoon-Ho Choi, Muhammad Bilal, and Jong-Wook Jang

Sensors

Domestic

[KCI]Real-Time User Login Account Access Management Using Mobile App

Seok-Hwan Choi, Jun-Ho Kwon, Yoon-Ho Choi

KIISE Transactions on Computing Practices

[KCI]Development of Android App for Supporting Smooth Multimedia Streaming Service Using Frame Buffer

Sang-min Seo, Joonho Kwon, Yoon-Ho Choi

Journal of Korean Society For Internet Information

[Patent]Secure Account Access Management Method Using Mobile App

Yoon-Ho Choi, Howon Kim

no. 10-2015-0006030, Korea